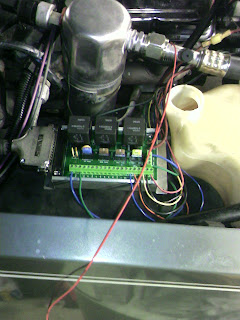

Well, busy day. You can see the pictures. The Megasquirt in the floor, the relay board all hooked up, and the original fuel feed line on the ground. The hardest part? Getting that damn fuel line out. I still have to extract the old vapor return line. That's not going to be fun, either. I did manage to clean up some rusty stuff and hit it with Rustoleum. Hopefully that'll arrest it for at least a little while.

Well, busy day. You can see the pictures. The Megasquirt in the floor, the relay board all hooked up, and the original fuel feed line on the ground. The hardest part? Getting that damn fuel line out. I still have to extract the old vapor return line. That's not going to be fun, either. I did manage to clean up some rusty stuff and hit it with Rustoleum. Hopefully that'll arrest it for at least a little while.

The battery is back in the car, and all the sensors except the TPS are hooked up. I still need to find a TPS connector. I'll be in D.C. next weekend. Hopefully I can hit a scrap yard after I get

back and pick up a TPS plug. I've also made my hose list. Lots of fuel line and some vacuum line. I've already picked up a flaring tool and a tube bender, and a fuel filter. Two weekends from now should be a fun one. I'll mount the pump and filter, and run the fuel and return lines.

back and pick up a TPS plug. I've also made my hose list. Lots of fuel line and some vacuum line. I've already picked up a flaring tool and a tube bender, and a fuel filter. Two weekends from now should be a fun one. I'll mount the pump and filter, and run the fuel and return lines.After that? Charge the battery while I'm putting the gas tank back in, put some gas in it, and try to start it. I loaded all the default settings for the Megasquirt into the computer today. The guy that designed the unit has a TPI Chevy, so all the default stuff is for that engine. It should be painfully close on the tune.

I also need to figure out how to mount my fast idle thingy. May have to drill and tap the throttle body. Stay tuned.